Wheat Harvesting and Flour Production Process in Turkey

An In-Depth Look at Turkey's Wheat Harvesting and Flour Production Processes

Introduction to Wheat Harvesting and Flour Production in Turkey

Wheat harvesting and flour production are integral components of Turkey's agricultural sector, playing a critical role in both domestic food supply and international trade. Turkey's agricultural landscape, with its diverse climates and fertile soils, provides an ideal environment for cultivating a variety of wheat. The journey from wheat cultivation to flour production involves meticulous processes, advanced technologies, and traditional practices that ensure high-quality output. In this blog, we delve into the stages of wheat harvesting and flour production in Turkey, examining the key factors that contribute to the industry's success and efficiency.

Wheat Harvesting in Turkey

Wheat Varieties

Types of Wheat: Turkey primarily cultivates hard red wheat, durum wheat, and soft wheat. These varieties are selected based on their suitability for various climatic conditions and end uses. Hard red wheat is known for its high protein content, making it ideal for bread-making. Durum wheat is used primarily for pasta and semolina, while soft wheat is suitable for pastries and cakes .

Cultivation Practices

Planting Seasons: Wheat planting typically occurs in autumn, with harvesting taking place in late spring to early summer. The timing ensures that the wheat matures under optimal weather conditions, maximizing yield and quality.

Agricultural Practices: Modern farming techniques are employed, including crop rotation to maintain soil fertility, proper irrigation methods to ensure adequate water supply, and the application of fertilizers and pesticides to enhance yield and quality. These practices are vital for sustainable wheat production.

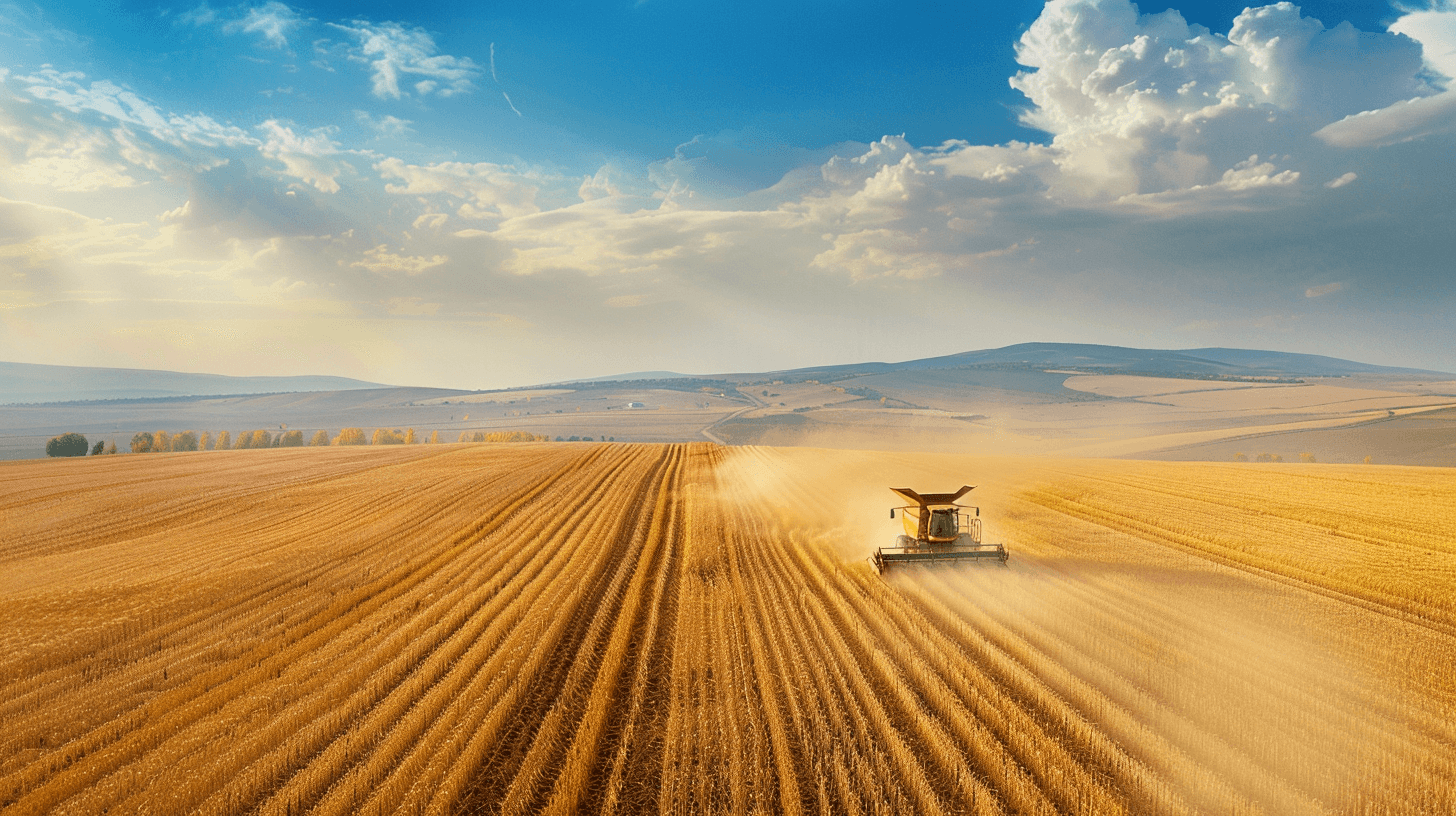

Harvesting Techniques

Mechanical Harvesting: Most wheat harvesting in Turkey is done using combine harvesters. These machines efficiently cut, thresh, and clean the grain in one operation, significantly reducing labor costs and time.

Manual Harvesting: In some smaller or traditional farms, manual harvesting methods are still employed. While less common, these methods are used in regions where machinery may not be feasible due to terrain or farm size.

Post-Harvest Processing

Cleaning and Storage

Initial Cleaning: After harvesting, wheat undergoes initial cleaning to remove impurities such as stones, chaff, and other foreign materials. This step is crucial to ensure the quality of the final product.

Storage Facilities: Proper storage in silos or warehouses is essential to maintain the quality of wheat. Conditions such as temperature and humidity are carefully controlled to prevent spoilage and pest infestation. Advanced storage techniques and technologies help in preserving the wheat until it is ready for milling .

Quality Control

Inspection: Quality checks are conducted to ensure the wheat meets the required standards for moisture content, protein levels, and absence of contaminants.

Grading: Wheat is graded based on its quality, which determines its suitability for various types of flour production. This grading process ensures that only the best quality wheat is used for premium flour products.

Flour Production Process

Milling Techniques

Modern Milling: Most of Turkey's flour production is conducted in modern milling facilities equipped with advanced technology to ensure high efficiency and quality.

Steps in Milling:

Cleaning: Wheat is thoroughly cleaned to remove all impurities.

Conditioning: The grain is tempered by adding moisture to prepare it for milling.

Grinding: The conditioned wheat is passed through rollers to break it into flour and bran.

Sifting: The ground wheat is sifted to separate flour from bran and germ.

Types of Flour Produced

Bread Flour: High gluten content, suitable for bread-making.

Whole Wheat Flour: Contains all parts of the wheat kernel, offering higher nutritional value.

Semolina: Coarse flour made from durum wheat, used for pasta and couscous.

Pastry Flour: Lower protein content, ideal for pastries and cakes .

Packaging and Distribution

Packaging: Flour is packaged in various quantities, from small retail packs to large bulk sacks, depending on the market needs. Proper packaging ensures the flour remains fresh and uncontaminated during transit.

Distribution: Turkey's strategic geographical location facilitates efficient distribution to both domestic markets and international export destinations. Advanced logistics systems and transportation networks ensure timely delivery of flour to various markets.

Challenges and Innovations

Economic and Environmental Challenges

Economic Factors: Fluctuations in fuel and raw material prices can affect production costs. The wheat industry must navigate these economic variables to remain competitive.

Climate Impact: Adverse weather conditions and climate change pose risks to wheat yields and quality. These environmental factors require farmers to adopt adaptive strategies to maintain production levels .

Technological Innovations

Sustainable Practices: The adoption of sustainable farming practices and eco-friendly technologies in milling helps reduce the environmental impact of wheat production. These practices include using renewable energy sources and implementing water-saving irrigation techniques.

Advanced Machinery: The use of state-of-the-art milling equipment and quality control systems enhances efficiency and product quality. Technological advancements in machinery and processes ensure that Turkey remains a leader in the global flour market.

About Eflani FlourEflani Flour is a prominent player in the Turkish flour industry, known for its commitment to quality and innovation. Utilizing advanced milling technologies and stringent quality control measures, Eflani Flour produces a wide range of high-quality flours suitable for various applications. Their dedication to sustainable practices and customer satisfaction makes them a preferred choice for both domestic and international clients. Discover more about Eflani Flour and their premium products by visiting Eflani Flour website.