Comprehensive Guide to Flour Factories and Producers in Turkey

Flour production in Turkey is a cornerstone of the nation’s agricultural and industrial sectors. With roots tracing back to the Ottoman Empire, the industry has evolved through traditional and modern methods to become a global player. This comprehensive guide explores the historical progression, major producers, regional distribution, quality standards, export markets, and the challenges and opportunities within Turkey’s flour industry. Through understanding these aspects, we gain insights into the industry’s pivotal role in Turkey’s economy and its global impact.

History of Flour Production in Turkey

Flour production in Turkey has a rich history, evolving significantly from the Ottoman Empire to the present day. From traditional milling methods to the advanced industrial processes of today, Turkey's flour production industry has seen numerous changes and improvements. This section will cover the historical development of flour production and its adaptation to modern times.

Ottoman Era: Uncovering the traditional methods used in flour production and the significance of flour production during this period, highlighting how it sustained the empire.

Republican Era: Exploring the impact of industrialization on flour production and the evolution of the industry in modern Turkey, focusing on key advancements and milestones.

Major Flour Producers in Turkey

The leading flour producers in Turkey contribute significantly to the industry with their diverse product offerings and innovations. These companies have built their reputations on quality, reliability, and customer satisfaction. This section will provide detailed profiles of Eflani Un, Eksun, and Tellioğlu, showcasing their histories, production capacities, and product ranges.

Company Profiles:

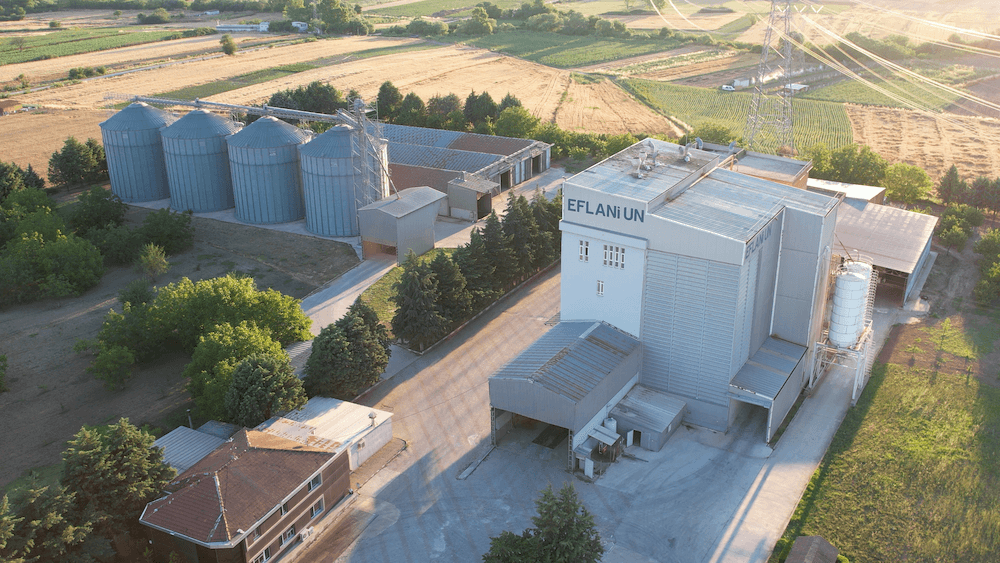

Eflani Un:

Eflani Un is a well-established company with years of experience in the industry. Known as one of the oldest and most reputable flour producers in Turkey, Eflani Un has consistently maintained high standards in production and customer service.

Production Capacity: Eflani Un boasts a high production capacity with modern facilities equipped to handle significant output. The daily production capacity exceeds 500 tons, allowing the company to meet large-scale demands both domestically and internationally.

Eksun:

Eksun is known for its innovative approaches and high-quality standards. The company operates with a customer satisfaction-oriented service approach, consistently seeking to improve and expand its product offerings.

Production Capacity: Eksun's daily production capacity exceeds 1.500 tons. The company operates with state-of-the-art production facilities, ensuring efficiency and maintaining the highest standards of hygiene and quality.

Ulusoy Un:

Ulusoy Un, established in 1969, is a prominent flour producer in Turkey, known for its quality and innovation. The company operates five production facilities in Samsun, Tekirdağ, and Hatay, with a combined daily production capacity of 4,415 tons. Ulusoy Un integrates traditional methods with modern technology to ensure high-quality products.

Production Capacity: Ulusoy Un’s daily production capacity reaches 4,415 tons, supported by its advanced production facilities.

Regional Distribution of Flour Factories

The geographical structure of Turkey has led to the concentration of flour factories in specific regions. Each region offers unique advantages that contribute to the overall productivity and efficiency of flour production. This section will discuss the distribution of flour factories across Turkey and their regional significance.

Marmara Region:

The Marmara Region is one of Turkey's most important flour production centers, serving both domestic and export markets. Its strategic location and advanced infrastructure make it a hub for large-scale flour production.

Central Anatolia Region:

The Central Anatolia Region, known as Turkey's grain warehouse, holds significant importance in flour production. The abundance of high-quality wheat in this region makes it a key area for flour manufacturing.

Quality Standards and Certifications

Quality standards and certifications in flour production are crucial for product safety and customer satisfaction. Adhering to these standards ensures that flour producers maintain high levels of hygiene, safety, and quality in their operations. This section will discuss the quality standards and certifications held by Turkish flour producers.

ISO Certifications:

Common ISO certifications held by Turkish flour producers set the industry’s quality standards, ensuring that products meet international benchmarks for safety and quality.

Benefits: ISO certifications provide various benefits to both producers and consumers, including improved process efficiency, enhanced product quality, and increased consumer trust.

Other Certifications:

HACCP and Halal certifications, among others, play a vital role in enhancing the quality and safety of Turkish flour products. These certifications demonstrate a commitment to food safety and cater to specific market needs.

Benefits: These certifications offer significant benefits in terms of product quality and safety, helping producers to access new markets and meet diverse consumer requirements.

Export Markets for Turkish Flour

Turkey plays a significant role in flour exports, supplying various regions around the world. The strategic location and high-quality production capabilities of Turkish flour producers make them competitive in the global market. This section will explore the main export markets for Turkish flour and their importance.

Middle East:

The Middle East is one of the largest export markets for Turkish flour, contributing significantly to the sector. The region's proximity and strong trade relations with Turkey enhance the export dynamics.

Africa:

Africa is an emerging market with great potential for Turkish flour exports. The continent's growing population and increasing demand for high-quality flour make it a key target for Turkish producers.

Challenges and Opportunities in the Flour Industry

The Turkish flour industry faces various challenges and opportunities on both local and global levels. This section will cover the main challenges and the proposed solutions, as well as the opportunities in the industry. Understanding these dynamics is crucial for the continuous growth and adaptation of the industry.

Challenges:

The primary challenges facing the industry include:

Fluctuations in raw material prices: Affecting production costs and profitability.

Intense competition: Both domestically and internationally, requiring constant innovation and efficiency.

Export barriers and logistical issues: Complicating the distribution and delivery of products.

Solutions: Potential solutions and strategies to overcome these challenges include:

Exploring alternative raw material sources: Ensuring a stable supply chain and cost management.

Utilizing efficiency-enhancing technologies: Improving production processes and reducing waste.

Discovering new markets and deepening existing ones: Expanding the customer base and increasing market share.

Opportunities:

Growth opportunities in domestic and international markets include:

Increased demand for whole wheat and organic flours due to health consciousness: Capitalizing on trends towards healthier eating.

Development of new export markets: Identifying and entering emerging markets with high potential.

Diversification of product offerings through technological innovations: Meeting specific consumer needs and staying competitive.

Strategies: Recommended strategies to leverage these opportunities include:

Expanding the product range: Introducing new and innovative products to attract different customer segments.

Enhancing marketing and promotional activities: Increasing brand visibility and customer engagement.

Increasing investment in R&D: Developing advanced products and processes to maintain a competitive edge.